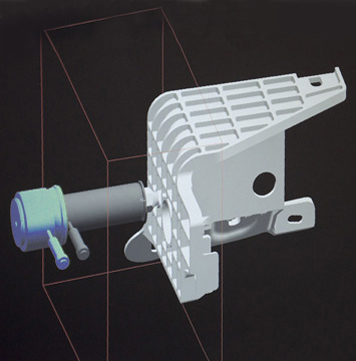

The construction of the molding tools is being developed on the basis of the customer´s specific requirements.

We are using the most up to date CAD CAM systems for our customers. The mold shop maschinery is connected directly to our CAD systems.

Our extreme flexibility serves our customers with a short leadtime for the building of the molding tools. A CAD data exchange can be processed in all common formats.

Our tool and mold shop is characterized by long time experience and precise work.

Precise and high qualitiy tools as well as high grade machines and raw material are a guarantee for efficient final goods. Having our own mold shop allows short lead times for new tools, tool changes and maintenance. We provide tooling and final goods from one source which enables us to react quickly on short notice customer´s requests.

The modern machinery consists of DMG CNC Universal milling machines, HSC milling machines, CNC sinking EDM machine, CNC wire eroding machines and several manual machines. The maximum tooling dimensions are 1100 x 700 x 1000 mm.

Since the foundation of Haller Kunststofftechnik GmbH we are manufacturing technical plastic parts for variable use in all industries. The flexible and multifaceted machinery is adjusted to the individual customer needs and requirements.

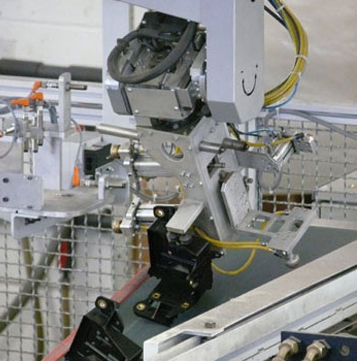

It consists of 36 injection molding machines with a clamp force of 250-5000 kN and a possible weight/part of 0.5-1000 g.

Throughout the years the production line has grown with the complex and various customer´s requirements.

We have a multi-shift operation with a fully and a semi automated manufacturing. We are working with all popular thermoplastic resins. Our product range reaches from single and multi component parts to mounting the assembly as well as injection molding around inserts.